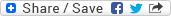

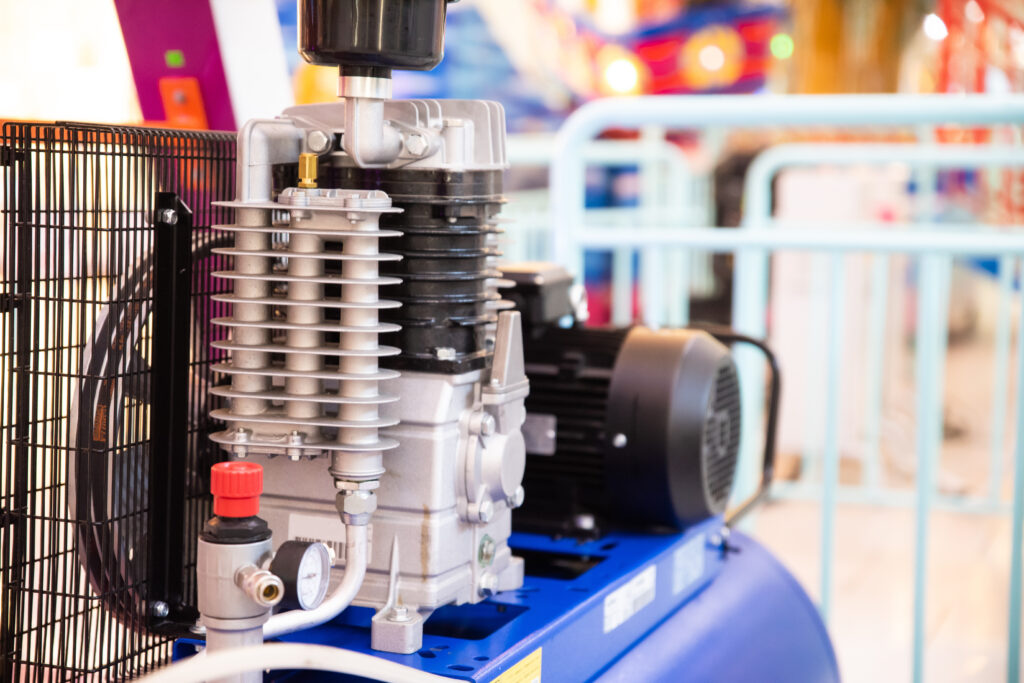

Positive displacement blowers also called rotary engine blowers or PD blowers, are pieces of machinery utilized for moving fuel or air for various purposes. The PD blowers generally propel air from an exhaust tube going to a nozzle, directing the air to the desired location where it’s bound to carry the required weight to complete the task.

A rotary engine or positive displacement engine has actually been around for decades. It’s a popular option for employment in industries requiring heavy machinery for their operations. Such industries require the force applied by the PD engine for moving massive objects.

On the other hand, a negative displacement engine doesn’t have a nozzle. It’s, instead, driven by a rotor or fan set to pull or push air through the cylinder. Depending on the application, air can then be blown out of the cylinder or be directed into the cylinder.

How Do PD Blowers Work?

Positive displacement blowers have two types: lobe and screw. You have to understand each of them to know how PD blowers work. Take a closer look at the lobe positive displacement blower and screw positive displacement blower below.

- Lobe PD Blower – A PD lobe blower is a machine conveying a relatively constant gas volume from an inlet to a discharge point. It follows the external compression principle, also known as the isochoric compression principle. In this principle, the machine forces the air or gas into a system with back pressure or resistance to achieve the needed increase in pressure. That’s why lobe positive displacement blowers aren’t considered compressors. The casing and rotating parts’ configuration fix the amount of gas it can handle.

- Screw PD Blower – Rotors turn in opposite directions in a screw positive displacement blower to maintain alignment precisely through timing. A series of working chambers are formed between the casing wall and the rotors when the rotors mesh.

The gas in a positive displacement screw blower is sucked from the suction or the intake side and trapped between the casing, rotors, and the cover. It’s then discharged by transporting it to the compression side where the gas or air is compressed, or the working chamber shrinks. A steady, non-pulsating airflow supply results from the internal compression. It maximizes the lifespan of the blower by minimizing vibration and maintenance.

Importance Of PD Blowers In A Variety Of Industries

Helping increase the air filters’ life is one of the positive displacement air blower’s most important functions. By aiding in the air filter’s self-cleaning mechanism, PD blowers improve the air filter’s overall performance. The process becomes more efficient with a larger filter.

Another essential positive displacement air blower function is generating heat and transferring it from one area to another. It’s done by generating heat using the air and pushing the air to the upper atmosphere from the lower atmosphere. In several industries that operate through this kind of mechanism, the process is proven efficient.

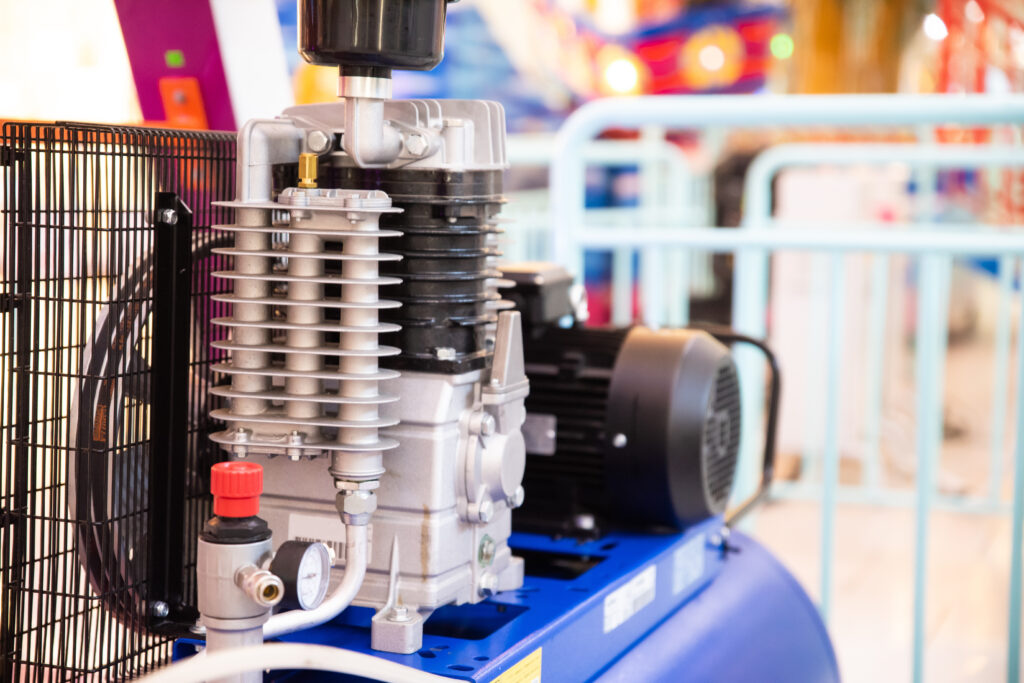

Other things that make positive displacement blowers important are their reliability and user-friendliness. Even at high pressures, PD air compressors can maintain a constant airflow. These blowers are also easier to maintain. They’re more cost-effective compared with other types of machinery.

The machine’s easy installation process makes positive displacement blowers well-established and renowned among various industries as well.

Because a positive displacement blower has specific uses or functions that other air compressor forms can’t accomplish or don’t possess, there’s no substitute for it among many industries. Note that PD blowers come in a range of models and offer a mix of features. The good news is that you can now have custom PD blower packages. You can check out websites like Nwflowtech.com to learn more about these packages.

Benefits Of Using Positive Displacement Blowers

Utilizing positive displacement blowers brings numerous benefits. The PD blowers can help in a lot of specific and significant ways, depending on each industry. Meanwhile, positive displacement blowers also have advantages that they generally carry in any industry. Below are some of those general benefits:

1. Saves Time And Effort

A positive displacement blower can help in reducing the time it takes to clean workplaces. It can be one long and laborious task to clean up grimy and dust-ridden areas, especially if there’s an inconsistent flow of air. Wide areas can be cleaned up efficiently with the help of positive displacement blowers. Not only can it save you time and effort, but also allow your employees to focus on more important tasks other than cleaning up waste.

2. Lowers The Cost Of Operations

To lower their cost of operations, many factories have installed PD blowers. Several leading manufacturing companies worldwide also started investing in PD blowers because using such a high-performance system cuts their costs by up to 50%. By using positive displacement machines, these businesses can increase their profit.

Moreover, companies can regulate the machine’s output, so they can also reduce the operating cost by getting rid of extra expenditures. Investing in a positive displacement system is also a great idea as there are no additional expenses or costs incurred for labor, fuel, and raw materials. Hence, companies not only can effortlessly save but also effortlessly gain more returns.

3. Reduce The Amount Of Waste

Moreover, companies using PD systems can lessen the amount of waste going into landfills. Companies can pick and place materials on the conveyor belt using a positive displacement blower, making it easier for them to pick up and put the trash into the recycling bins.

Big industries produce massive residues from their operations. That’s why they can cause tremendous environmental impact if they don’t dispose of their waste correctly. Fortunately, enterprises consistently observe proper recycling nowadays. Industries that are now putting more emphasis on appropriate recycling include food manufacturing, pharmaceuticals, as well as oil and gas. They utilize positive displacement blowers to make recycling easier.

How To Maintain A Positive Displacement Blower

Now that you know how a PD blower is the heart of many industrial operations, you’d surely agree that it’s important to keep it working. It has to continue keeping your oils flowing, your conveyor belts moving, and your employees working for as long as possible. Taking good care of a PD blower means little to no downtime in operations. However, the machine works so well that people forget to take care of their positive displacement system from time to time. But, your business stops working when your PD machine stops working. Here are some useful tips to ponder on to maintain a positive displacement blower:

1. Check The Oil Levels Before Starting Your PD Blower

Never run or start your PD blower while it’s low in oil. There’s no going back when you launch the machine. That’s why it’s a good idea to call the maintenance crew as you’re turning on the switch. An immediate failure on the machine’s gears will result to turning on the blower while low on juice. More damage will occur the longer it goes on. The end clearances will change, and the bearings will fail as the rotor gets thrusted into the free end plate.

Consider putting up and following a procedure for checking all of the machinery before you get the conveyors going. It will take just several minutes, but it can save your PD blower from damage and your business from lost time.

2. Keep The Lubricating Oil Clean

You also have to keep the oil clean aside from checking the levels. Just like a car or a motorcycle, a PD blower needs lubrication so that it can keep the rotors moving smoothly. Depending on your facility’s condition, you have to change the motor oil in your positive displacement blower every 500-1000 hours. The harder you work your PD blower and the dirtier the facility, the more often you should be changing the machine’s oil.

3. Check For Signs Of A Starved Inlet

When airflow that enters the blower isn’t sufficient, your positive displacement machine could be suffering from a starving inlet. With a starved inlet, the airflow isn’t cooling the blower down as it works. Check for its signs, like the yellowish color of the rotors. It indicates the internal temperature to be hitting around the 430-degree mark. At this point, your PD blower is overheating. It’s time to take action as soon as you see the strange discoloration.

4. Prevent Over-pressure

Always keep in mind that your PD blower is a machine. Nothing will stop it from doing what it’s designed to do, not even a blocked air pipe. Unless the gears fail, it will keep going. The problem when there’s something stuck in the air pipe is that the blower will self-destruct while the machine wants to keep moving.

Prevent over-pressure by having a pressure release valve installed on each blower’s discharge. If the problem persists, better call the pros to fix it.

Conclusion

The PD blowers are extremely beneficial for many different industries. They’re indispensable these days. Due to their cost-effective design and functionality, their popularity never diminishes. The various types of positive displacement blowers available for each industry make these machines even more impressive. There’s a specific PD blower type that suits a particular business. Therefore, you’ll never run out of options.

A positive displacement blower is your business’ heart and soul, so treat the machine as a family member. Your conveyor belts won’t move, and pumps won’t pump if this piece of equipment gets damaged. Properly maintain your PD blower’s parts for it to keep your business moving.

P.S: – If you liked this article, please leave a comment below. We value your opinions a lot. Also, for more online learning opportunities, join our EAT Community, where you can make some money making the planet better!

Related Articles and Resources:

- Is Green Engineering the Future?

- 3 DIY Eco-Friendly Cleaning Recipes for Home or Business

- How To Make Your Business More Eco-friendly